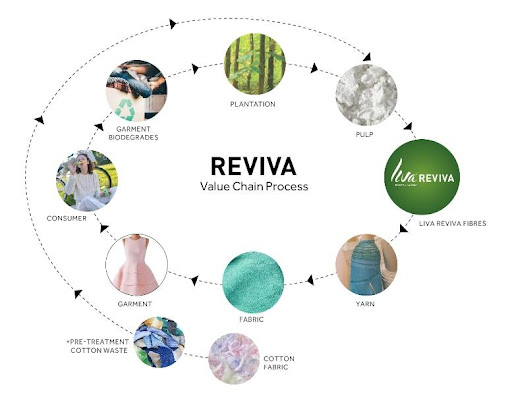

Taking a crucial step in our journey towards circularity with Liva Reviva, containing 30% textile waste

February 07, 2023Every year, significantly large amount of textile waste is generated worldwide out of which very little quantity gets recycled into new clothing. Large quantity textile waste generated is leading to significant increase in environmental pollution. To tackle the textile waste challenge the big fashion brands and the textile value chain are planning their next steps more responsibly, that will lead to decrease in textile waste generation in coming years.

We have taken an aspirational aim to increase the offering of circular fibre in textile products up to 100,000 tons by the year 2024 using textile waste and alternative feedstock that will enable in reducing environmental footprint of textile waste and enhance circular economy.

Being one of the leading global producer and supplier of Man-Made Cellulose Fibre (MMCF), we have developed Liva Reviva with 30% textile waste content. Circularity has been a key goal for us and its commitment towards contributing to sustainable development. In 2019, we launched Liva Reviva with 20% pre-consumer waste content. Our R&D efforts towards developing a circular economy model and increasing the utilisation of alternative textile waste feedstock has led to several innovations that have shown promising results and are in various stages of development, starting from lab level, to a pilot and some have already reached the commercial level.

We have also been able to successfully stabilize production of the Recycled Claimed Standard (RCS) certified product, Liva Reviva which now contains 30% of textile waste and rest 70% of dissolved wood pulp from sustainable forests (FSC certified).

The quality of the fibre remains comparable to the quality of fibre produced using virgin wood-based pulp. Making Liva Reviva a high-quality fibre that finds widespread applications amongst major global brands. Birla Cellulose’s current efforts are concentrated on developing products made with industrial waste, post-consumer waste and alternate feedstock. The use of alternate feedstock in total production would help in reducing the waste and a climate friendly solution.

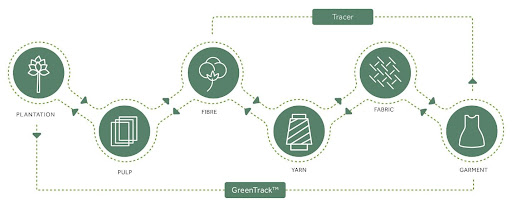

Liva Reviva can be tracked with help of Green Track ™ platform. The Green Track™ platform designed by us helps track the origin of the fibre and brings transparency and traceability in the long and complex textile value chain, by using block chain technology. Through the Green Track™ platform, we along with our value chain partners will be able to track textile recycle material flow in the supply chain that too in real-time, from certified forests to the end consumers by scanning a QR code and help the consumer make an informed purchase decision.

To know more about Liva Reviva, click here.