Optimizing Yarn Quality in Bamboo Ring Compact Yarn Production: A Case Study

August 16, 2024In the dynamic realm of textile manufacturing, ensuring the consistent quality of yarn is paramount, especially for specialized products like Ne 60s Bamboo Ring compact yarn. A recent incident at a spinning mill, which resulted in a sudden decline in yarn CSP (Count Strength Product) to 2180 units from the usual 2500 units, underscores the critical nature of process control and machine settings in maintaining yarn quality. This article delves into the troubleshooting process, root cause analysis, and corrective actions taken to restore the yarn quality.

Troubleshooting the Yarn Quality Decline

The spinning mill observed a notable increase in yarn breaks during the ring spinning process, prompting a comprehensive investigation. The analysis revealed an increase in long thin and thick faults, as indicated by the auto coner online Classimat value from the Uster Quantum 3 clearer yarn body diagram. This finding suggested inconsistencies in the yarn that were not typical of the usual production standards.

Analyzing Process Parameters

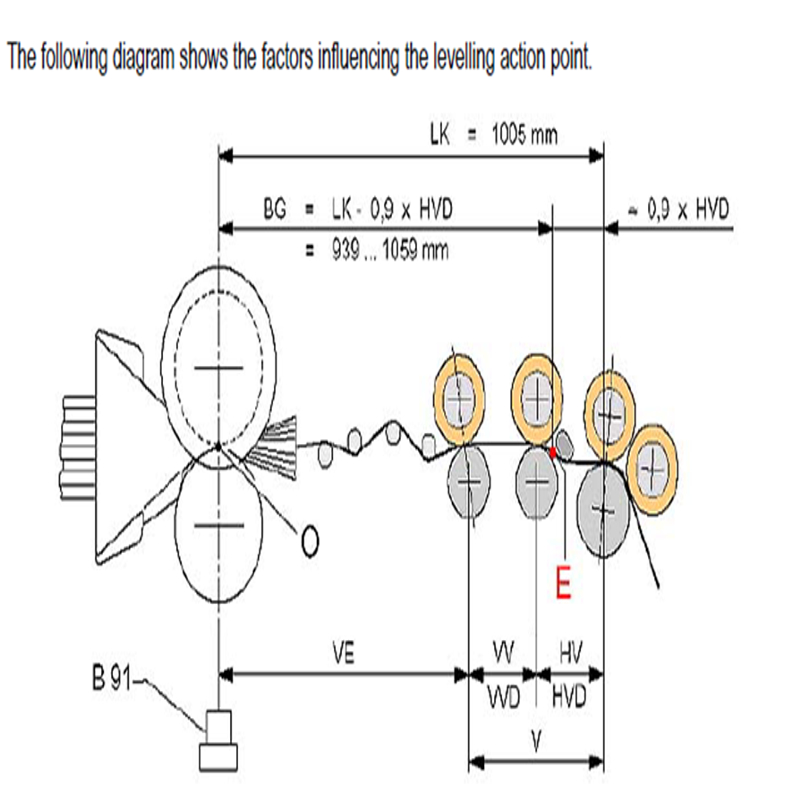

A detailed review of the process parameters highlighted a discrepancy in the levelling action point (LAP) value of the finisher draw frame. The finisher draw frame is critical in ensuring the evenness of the sliver, which directly impacts yarn quality. The draw frame machine settings, particularly the auto leveler settings, play a pivotal role in this process.

Impact of Draw Frame Machine Setting on Yarn Quality

The draw frame machine's settings significantly influence yarn evenness, strength, and elongation. The auto leveler in the finisher draw frame is responsible for controlling the uniformity of mass in the output sliver, making it the final stage in eliminating errors before spinning.

The auto leveler's efficiency is influenced by several variable parameters:

-

Correction Length: The length over which corrections are made.

-

Correction Time: The time taken to make these corrections.

-

Time Delay (LAP or Cp): The delay before corrections are applied, which can be adjusted.

Key Adjustable Parameters

The main adjustable parameters in the draw frame machine that affect the time delay (LAP or Cp) include:

-

Main Draft Roll Setting Distance (HVD)

-

Break Draft (VV)

-

Delivery Speed

At the mill, the LAP or Cp value was checked against differential values to determine the best uniformity value and coefficient of variation percentage (CV%). Adjusting these settings correctly is crucial for optimizing sliver quality, which in turn impacts the final yarn quality.

Implementing Corrective Actions

After identifying the discrepancy in the LAP value, the mill's team made adjustments to the time delay setting in the draw frame machine. This adjustment aimed to improve the uniformity of the output sliver. Table 1 illustrates the improvements in sliver quality, with notable reductions in unevenness (U %) and coefficient of variation (CV %).

Table 1: Sliver Quality - U % and CV %

| Parameter | Before Adjustment | After Adjustment |

| U % | Higher | Lower |

| CV % | Higher | Lower |

Following the adjustments, yarn samples were produced to evaluate the impact on yarn quality. The results were promising, showing a significant improvement in Yarn CSP, nearly reaching the original average of 2500 units.

Table 2: Yarn Quality - IPI and CSP

| Parameter | Before Adjustment | After Adjustment |

| IPI | Higher | Lower |

| CSP | 2180 | 2498 |

Summary and Conclusion

The case study underscores the importance of precise machine settings in maintaining yarn quality. The initial decline in Yarn CSP was traced back to suboptimal settings in the finisher draw frame's auto leveler. By adjusting the LAP or Cp value and optimizing other machine settings, the mill successfully restored yarn quality to its expected standards.

This incident highlights several key points for textile manufacturers:

-

Regular Monitoring: Continuous monitoring of machine settings and yarn quality metrics is crucial.

-

Root Cause Analysis: Systematic troubleshooting helps identify the exact cause of quality issues.

-

Optimization of Machine Settings: Fine-tuning machine parameters can significantly impact the final product quality.

Maintaining high standards in yarn production requires a proactive approach to process control and a deep understanding of the machinery involved. This case study serves as a valuable reference for textile mills aiming to optimize their production processes and ensure consistent yarn quality.